Manufacturing Gets Smarter : AI Trends to Watch

Manufacturing Gets Smarter: AI Trends to Watch

Key Takeaways

Smart manufacturing in 2025 is fueled by AI-driven technologies that boost efficiency, quality, and agility. These insights equip you to implement practical AI innovations that transform operations, reduce costs, and empower your workforce. Embracing AI adoption and emerging technology is essential for maintaining a competitive edge in the evolving manufacturing landscape.

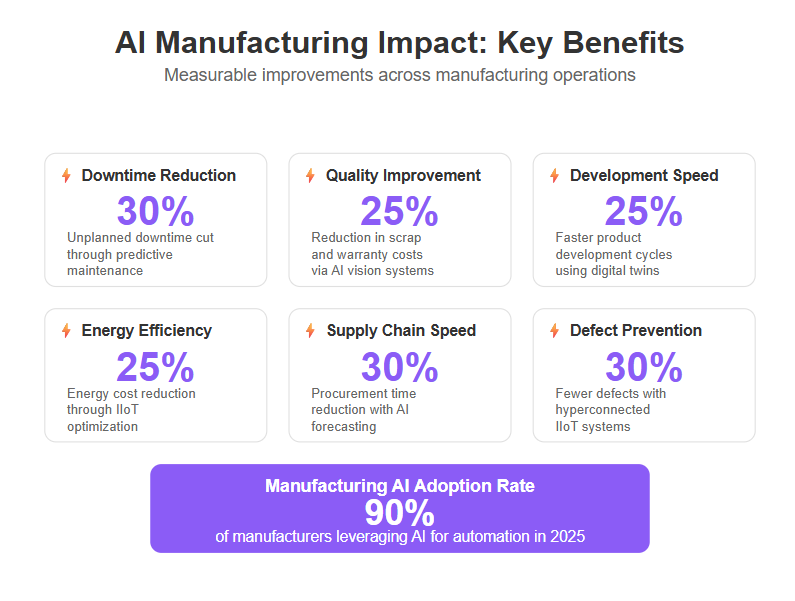

- Leverage AI-driven automation and predictive maintenance to enhance production efficiency and reduce downtime, cutting unplanned downtime by up to 30% while speeding production cycles and reducing human error.

- Deploy AI-powered computer vision for near-instantaneous defect detection, slashing scrap rates and warranty costs by up to 25% without slowing quality control.

- Build hyperconnected factories with IIoT to optimize energy use, reduce defects by 30%, and enable real-time process adjustments for agile, adaptive production.

- Use digital twins combined with AI analytics to run virtual simulations, anticipate bottlenecks, and reduce product development cycles by 25%—all while minimizing downtime.

- Embrace Industry 5.0 cobots and AI tools to enhance worker safety, boost flexibility, and upskill your workforce for hybrid human-machine collaboration.

- Integrate AI and blockchain in supply chains to achieve dynamic demand forecasting, reduce procurement time by 30%, and ensure transparent, tamper-proof tracking.

- Implement edge computing alongside multi-layered cybersecurity to enable millisecond decision-making and protect against a 35% increase in cyber threats targeting smart factories.

- Drive digital transformation with clear roadmaps and upskilling to overcome 70% of common implementation failures and embed AI tools that empower your whole team.

- AI adoption gives manufacturers a competitive edge by enabling advanced market intelligence, benchmarking, and performance improvements.

- Emerging technology plays a crucial role in enhancing efficiency across manufacturing operations, from supply chain optimization to workplace safety.

Ready to turn these AI trends into real-world results? Dive deeper to learn how smart manufacturing can future-proof your business in 2025 and beyond.

Introduction

What if your factory could predict a machine failure days before it happens—saving you thousands in downtime and repair costs?

Artificial intelligence is the driving force behind the industrial transformation of the manufacturing industry, enabling smarter, more efficient production processes. Welcome to manufacturing in 2025, where AI-driven automation and smart connectivity are redefining how products get made. The manufacturing sector is rapidly evolving due to AI integration and the widespread adoption of AI in manufacturing, leading to faster pace, higher quality, and factories transforming from rigid assembly lines into agile, data-powered ecosystems. These trends are shaping the near future of the manufacturing landscape, setting the stage for unprecedented innovation and efficiency.

For startups and SMBs aiming to scale quickly, as well as enterprises navigating complex tech adoption, understanding these trends isn’t optional—it’s essential. Embracing AI today lays the foundation for smarter workflows, better resource use, and competitive advantages tomorrow.

In the sections ahead, you’ll discover how:

- Predictive maintenance cuts unplanned downtime by up to 30% and extends equipment life

- AI-powered computer vision slashes defect rates and raises quality control speed

- The Industrial Internet of Things (IIoT) connects machines into a hyperresponsive network

- Digital twins let you test changes virtually before impacting the production line

- Collaborative robots empower workers and transform factory safety

- Advanced analytics and blockchain build resilient, transparent supply chains

- Sustainability efforts benefit from AI by trimming energy use and waste

Each trend will show practical strategies to help you get started without drowning in hype or complexity.

As manufacturing shifts from automation to intelligence, your next move could make all the difference. How are these AI-powered innovations actually transforming operations, and what’s standing between you and a truly smart factory?

We’ll explore these breakthroughs one step at a time, beginning with the backbone of smart manufacturing: AI-driven automation and predictive maintenance.

AI-Driven Automation and Predictive Maintenance: The Backbone of Smart Manufacturing

AI is no longer a futuristic concept in manufacturing—it’s now the driving force behind smarter, faster production. Predictive analytics powers predictive maintenance and enables smarter manufacturing operations by providing real-time insights and anticipating equipment failures. In 2025, nearly 9 out of 10 manufacturers are leveraging AI to automate workflows and sharpen operational efficiency.

Automation is further enhanced by AI agents and AI integration, which streamline manufacturing operations by connecting autonomous systems and optimizing business processes for seamless execution.

Key benefits include increased production efficiency, as these technologies reduce errors, minimize downtime, and optimize workflows.

Streamlining Production with AI Automation

Automated systems powered by AI are handling repetitive tasks, precision assembly, and complex scheduling, which means:

- Speeding up production cycles while maintaining high quality

Interconnected production systems and production networks enable seamless communication between machines and departments, optimizing workflows and ensuring efficient, resilient operations.

- Reducing human error and boosting consistency

- Freeing workers to focus on strategy and innovation instead of manual labor

Picture a factory line where machines communicate seamlessly, adjusting their pace to meet demand without wasting resources.

Predictive Maintenance: Cutting Downtime with Data

The real game changer? Predictive maintenance using AI. By continuously analyzing real-time sensor data, AI models predict equipment failures days or weeks before they happen, enabling proactive interventions that improve equipment performance through real-time monitoring and analytics.

This results in:

- Up to 30% reduction in unplanned downtime

- Extending machinery life by scheduling maintenance precisely when needed

- Lowering repair costs by catching issues early

- Reducing downtime and maintenance costs by detecting potential failures early

Imagine a machine that “texts” your team with a heads-up — fixing problems before they halt production.

Fast, Accurate Defect Detection with AI Vision

AI-based computer vision systems now inspect products in real time, spotting defects that human eyes might miss.

Benefits include:

- Real-time monitoring with AI vision systems ensures immediate defect detection and response

- Near-instantaneous quality control on production lines

- Reducing scrap and warranty costs by up to 25%

- Enabling immediate adjustments to keep output flawless

Visualize cameras catching every flaw as parts move, with alerts sent directly to operators, ensuring nothing slips through.

Key Takeaways for Manufacturers

- Automate repetitive tasks to improve efficiency and consistency

- Use AI-driven predictive maintenance to slash downtime and extend asset life

- Deploy AI computer vision for faster, more accurate quality inspections

AI-driven automation is enabling manufacturers to achieve greater agility and efficiency, empowering them to stay competitive in a rapidly evolving industry.

Ready to see how predictive maintenance can transform your operations? Check out How Predictive Maintenance Using AI Transforms Manufacturing Efficiency for strategies to optimize AI implementation.

AI-driven automation isn’t just about replacing manual work—it’s about enabling smarter decisions and more agile manufacturing that keeps you ahead in 2025 and beyond.

The Industrial Internet of Things (IIoT) and Smart Factory Connectivity

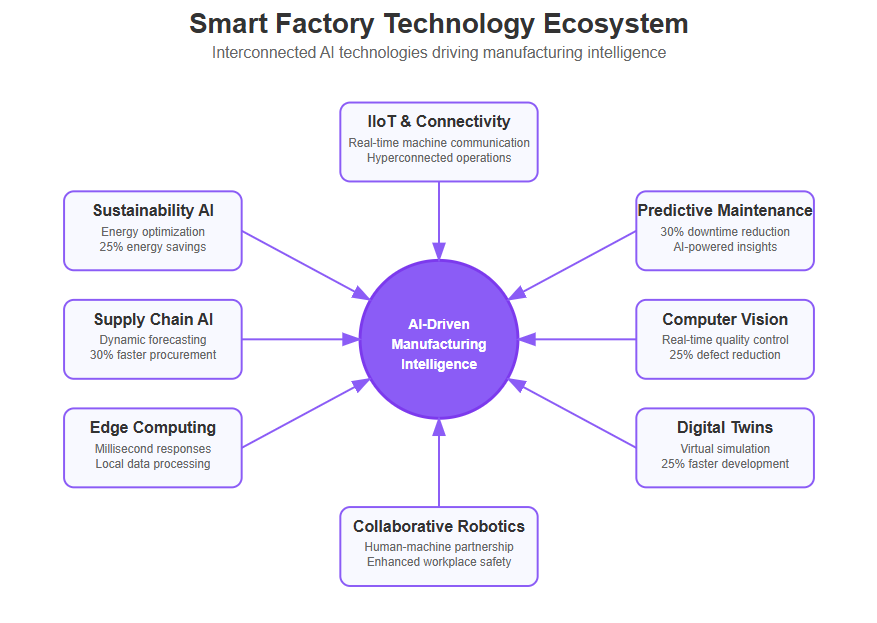

The Industrial Internet of Things (IIoT) is the engine behind today’s data-driven manufacturing ecosystems. It connects machines, sensors, robotics, and human interfaces in real time, creating smart factories that adjust and optimize themselves on the fly.

IIoT connectivity not only enables manufacturers to respond to market shifts more effectively, but also enhances supply chain visibility and transforms how supply chains operate, leading to greater resilience and adaptability.

Hyperconnected Machines Power Smarter Operations

Think of IIoT as the nervous system of modern manufacturing—linking every part of production into a seamless network. This real-time connectivity makes possible:

- Process optimization: adjusting equipment settings as production conditions change

- Asset tracking: monitoring materials and machinery location instantaneously

- Adaptive production lines: shifting workflows dynamically based on demand or supply

- Real-time production schedules: enabling hyperconnected machines to adjust and optimize production schedules instantly for maximum efficiency

This interconnected setup doesn’t just speed things up—it massively cuts downtime and waste by catching issues instantly.

IIoT Data Drives Efficiency and Quality Control

Tracking energy use and product quality becomes precise with IIoT insights. Smart factories leverage this data to:

- Minimize energy consumption by optimizing machine runtimes

- Detect quality deviations early using sensor analytics

- Predict equipment wear and trigger maintenance before breakdowns

- Support more effective supply chain management by providing real-time insights into inventory and logistics

For instance, manufacturers using IIoT report up to a 25% reduction in energy costs and a 30% drop in defects, thanks to constant monitoring and quick adjustments.

Adaptability and Agility at Scale

A hyperconnected factory is a flexible factory. The agility from IIoT environments helps businesses:

- Respond instantly to market fluctuations

- Scale production smoothly without costly downtime

- Maintain stringent quality standards across diverse product runs

Imagine a robotic arm pausing a batch when sensors detect an anomaly—and immediately alerting your control team—this instant reaction is now a reality for many in 2025.

Linking these technologies to AI analytics unlocks even deeper insights, turning raw IIoT data into actionable strategies. You can explore this in detail in our sub-page: Why AI-Powered Data Analytics Is Essential for Manufacturing Success in 2025.

Quotable nuggets for sharing:

- "IIoT turns factories into living networks that think, respond, and adapt in real time."

- "Smarter connectivity isn’t just faster—it's how manufacturing slashes costs and boosts quality."

Smart manufacturing relies on this continuous, data-driven dialogue between machines and humans, making your production smarter, faster, and greener.

At its core, investing in IIoT connectivity means turning your factory floor into an agile powerhouse—ready for whatever 2025 throws at it.

Digital Twins and Advanced Simulation: Virtualizing Manufacturing for Optimization

Digital twin technology is an emerging technology that is gaining traction in manufacturing as a live virtual replica of physical assets and processes, mirroring every nuance of your manufacturing environment in real time.

This technology is gaining traction as a critical tool for optimizing manufacturing environments.

They enable manufacturers to move beyond guesswork by providing a dynamic digital playground for testing changes before physical implementation.

Real-World Use Cases: Simulation and Scenario Planning

Here’s where digital twins shine:

- Continuous monitoring of factory equipment and processes to catch anomalies early

- Running what-if simulations to forecast outcomes of process tweaks

- Scenario planning that helps avoid costly downtime by anticipating failures or bottlenecks

- Simulating and optimizing entire production networks, enabling manufacturers to improve efficiency and resilience across interconnected operations

Picture this: instead of waiting weeks to see if a production change works, you run simulations instantly on your digital twin and spot defects or performance dips before they hit the line.

Accelerating Development and Quality Assurance

Digital twins turbocharge development cycles by mimicking physical behavior under various conditions, cutting prototyping times significantly.

Benefits include:

- Reducing downtime with predictive alerts

- Enhancing quality assurance through virtual testing of products and workflows

- Lowering maintenance costs by using predictive alerts and virtual testing to prevent equipment failures and minimize downtime

- Lowering costs by fine-tuning processes without interrupting production

A 2024 study found manufacturers using digital twins reduced downtime by up to 30% and cut product development cycles by 25%—gains that translate directly to your bottom line.

Integration with AI Analytics: The Smart Advantage

Pairing digital twins with AI analytics creates a powerful feedback loop: AI digests the rich data models to provide actionable insights and foresight. AI integration with digital twins leverages predictive analytics to deliver real-time insights, enabling manufacturers to anticipate issues, optimize operations, and drive digital transformation.

This combination lets you:

- Spot patterns invisible to human eyes

- Make smarter, faster decisions grounded in real-world data

- Adapt production in near real-time to shifting demands or conditions

Emerging capabilities also include cross-plant digital twins that allow enterprise-wide optimization, breaking silos and enabling a holistic manufacturing strategy.

Imagine an AI-driven cockpit showing your entire factory’s health and allowing you to run experiments on virtual lines before making real moves—that’s the future digital twins are unlocking.

The upshot? Digital twins aren’t just flashy tech. They’re critical tools for operational excellence—cutting downtime, boosting quality, and speeding innovation with precision and confidence. In the near future, digital twins are expected to play an even greater role in manufacturing optimization, as companies increasingly adopt advanced technologies to address industry challenges.

Industry 5.0 and Human-Machine Collaboration: The Future of Workforce Empowerment

Industry 5.0 flips the script on manufacturing automation by putting humans and machines on the same team. Instead of robots replacing workers, collaborative robots (cobots) now augment human skills—amplifying efficiency while keeping people in control. Industry 5.0 emphasizes the collaboration between human workers and advanced robotics, ensuring that technology complements rather than replaces the unique capabilities of people.

Human-Centered Smart Factories in Action

Cobots help enhance:

- Workplace safety by handling dangerous or repetitive tasks

- Flexibility through adaptive interactions with human operators

- Adaptability so workflows can shift quickly to new products or demands

Factory floors are being transformed as cobots and human workers collaborate, leading to safer, more efficient, and more adaptable manufacturing environments.

Think of a cobot handing parts to a technician instead of taking their job away—this means less wear and tear on the human body and more focus on creative problem-solving.

From Replacement to Upskilling

The narrative has changed: automation is no longer about cutting jobs, but about empowering workers with AI tools that open new roles requiring digital skills.

Workers today are:

- Managing AI-powered data analytics to spot production trends

- Overseeing cobot performance and adjusting digital workflows

- Engaging with AI-based decision-support tools for quality and maintenance

- Managing more complex manufacturing operations powered by AI, where they oversee efficiency, automation, and predictive maintenance

This shift means companies need to invest in training programs that help employees transition into hybrid tech roles, boosting job satisfaction and retention.

Embracing Cultural and Organizational Change

True Industry 5.0 success demands more than tech—it requires organizations to:

Foster a culture that values human-machine collaboration over pure automation, transforming industrial operations and reshaping organizational culture

Encourage continuous learning and flexibility in workforce roles

Support open communication between operators, engineers, and AI systems

Imagine an operator checking real-time AI insights on a tablet while working alongside a cobot, both adapting quickly to quality issues or production hiccups.

Quotable Takeaways

- “Industry 5.0 is about robots and humans working together, not against each other.”

- “Upskilling with AI tools isn’t optional—it’s essential for tomorrow’s manufacturing workforce.”

- “Human-centric smart factories create safer, more agile workplaces that thrive on collaboration.”

By combining AI-powered robotics with human creativity, Industry 5.0 is redefining manufacturing's future—making workplaces smarter, safer, and more empowering for the people who power them.

For a deep dive into cobots and their transformative impact, check out The Rise of Autonomous Robots: AI-Driven Manufacturing Transformation.

End-to-End Supply Chain Optimization through AI and Blockchain

AI is reshaping supply chains with real-time demand forecasting and logistics that adapt on the fly. This means fewer surprises and smarter decisions, even when markets shift quickly.

At the same time, blockchain technology guarantees transparent, tamper-proof tracking of goods and materials. It creates a shared, secure ledger for everyone involved—boosting trust and collaboration from suppliers to customers.

AI and blockchain are strengthening supply chain resilience by helping manufacturers adapt to supply chain disruptions, such as delays and shortages, through technology-driven solutions. Additionally, shifting trade policies are influencing supply chain strategies, encouraging reshoring and diversification to reduce dependency on specific countries and improve overall resilience.

Smarter Forecasting & Transparent Tracking

Here’s how AI and blockchain upgrade your supply chain:

- Revolutionize supply chain management by providing real-time insights and transparency, optimizing logistics, procurement, and inventory processes

- Predict demand dynamically using AI models that analyze historical data and external factors like weather or market trends

- Automate logistics to adjust routes, inventory, and delivery times in real time

- Use blockchain-ledger transparency for accurate tracking of shipments and inventory provenance

- Enhance supplier collaboration by sharing secure, immutable records

- Reduce stockouts and overstocks by syncing supply perfectly with demand

Imagine a factory where your system instantly predicts a spike in demand, notifies your suppliers, and reroutes shipments—all without human delay. That’s AI + blockchain in action.

Building Resilient & Responsive Supply Chains

Volatile markets are no longer a showstopper. Using AI and blockchain, businesses:

Build adaptive procurement strategies that pivot based on real-time data

Manage multi-tier suppliers with more visibility, spotting risks earlier

Accelerate order processing and delivery thanks to automated workflows

Ensure secure, auditable records that satisfy compliance requirements effortlessly

AI-driven platforms enhance supply chain resilience and supply chain visibility, enabling faster responses to disruptions and improving collaboration across the supply network.

For example, an SMB using AI-driven supply chain platforms cut procurement time by 30% and reduced urgent shortages by 40% in just six months.

Real-World Impact & Takeaways

- Dynamic demand forecasting empowers you to stay ahead of disruptions, helping manufacturers anticipate and mitigate supply chain disruptions with AI-powered insights.

- Blockchain transparency fosters trust and reduces fraud risk

- Combining these creates a supply chain that’s fast, flexible, and secure

“Unlocking true supply chain agility means trusting machines and ledgers to work together, cutting out manual guesswork.”

Picture a dashboard updating every shipment’s status instantly, alerting you only when action is needed—turning chaos into control.

Putting these tools into practice means your manufacturing operation runs smoother, with fewer costly surprises and happier customers.

Smart, connected supply chains aren’t just future talk—they’re actively transforming efficiency and resilience today.

For a deep dive into making these tech-driven strategies work in your business, see Unlocking Supply Chain Agility: AI’s Strategic Role in Manufacturing.

Sustainability and Green Manufacturing Powered by AI

AI and the Industrial Internet of Things (IIoT) are game-changers for cutting energy use and minimizing waste in manufacturing. Real-time data from connected sensors lets factories adjust processes instantly to avoid excess consumption and scrap. Additionally, AI optimizes the selection and use of raw materials, reducing waste and improving sustainability throughout the manufacturing process.

Optimizing Energy and Waste

Smart factories now use AI-driven insights to:

- Monitor and control energy consumption across production lines

- Detect inefficiencies causing material waste early

- Optimize production processes for greater energy efficiency and waste reduction

- Shift loads dynamically to off-peak energy hours, lowering costs and carbon footprint

These tactics directly support ESG goals, helping companies build more circular, sustainable manufacturing models.

Making ESG Goals Measurable

AI fuels data-driven circular manufacturing by:

- Tracking resource use and recycling rates continuously

- Predicting material lifespan to reduce overproduction

- Automating quality control to minimize scrap and defective parts

By leveraging these data-driven approaches, manufacturers can significantly enhance production efficiency while supporting ESG goals.

Factories applying these methods see up to 30% reductions in waste and energy savings of 15-25% annually, studies show.

AI in Emissions Monitoring and Compliance

Evolving regulations on emissions demand continuous oversight. AI-powered systems now:

- Track greenhouse gases and particulates in real time

- Alert operators to deviations before they escalate

- Generate compliance reports automatically, reducing paperwork and audit risks

Picture a dashboard lighting up green when emissions stay within limits, instantly flagging problems the moment they appear.

Real-World Examples and Benefits

Leading manufacturers deploy AI-based sustainability initiatives like:

- A Swiss automotive plant using AI sensor networks to cut water usage by 40%

- Electronics makers utilizing machine learning to optimize waste sorting and recycling

- Textile producers forecasting energy needs to reduce power peaks and costs

Why Sustainability Pays Off

Integrating AI for green manufacturing is more than good ethics—it’s a strong business move:

Compliance lowers risk and avoids regulatory fines

Smarter resource use reduces operational costs

Integrating AI-powered solutions can enhance efficiency and reduce operational costs

Sustainability builds brand value and attracts eco-conscious customers

Imagine your factory running leaner, cleaner, and more competitively—with AI lighting the way.

Sustainability isn’t a side project anymore; it’s woven into the smart factory’s DNA, powered by AI and IIoT. Start small, measure rigorously, and watch your green manufacturing gains stack up.

Edge Computing and Cybersecurity: Securing and Accelerating Smart Manufacturing

Smart manufacturing demands ultra-low latency data processing, and that’s where edge computing shines. Instead of sending all data to a central cloud, edge intelligence processes information right at the source—on machines or local hubs—to enable lightning-fast decisions.

The rapid adoption of edge computing and AI is putting unprecedented pressure on power grids and cybersecurity systems. As more devices connect and generate valuable insights, it becomes crucial to protect sensitive data from cyber threats within these environments.

Real-Time Impact of Edge Computing

This local data crunching is essential for several critical manufacturing functions:

- Real-time quality control that spots defects instantly, preventing waste

- Safety systems that react immediately to hazards, protecting workers and equipment

- Rapid operational responses that adjust settings or halt processes the moment anomalies appear

Picture this: a production line sensing a fault and stopping within milliseconds, not minutes—saving thousands in downtime costs.

Rising Cybersecurity Challenges

As factories become hyperconnected with IIoT devices and cloud networks, the attack surface multiplies. Cyber threats targeting manufacturing have surged by 35% in the last two years[source], exploiting weak links in device security and network protocols.

Here are the main risks to guard against:

- Device hijacking for ransomware or sabotage

- Data breaches exposing sensitive operational intel

- Supply chain attacks compromising software updates or hardware components

Best Practices to Fortify Your Smart Manufacturing Defenses

Protecting this complex ecosystem means going beyond basic IT security. Manufacturers need to:

Deploy multi-layered defenses combining edge firewalls, encryption, and anomaly detection

Regularly update and patch IIoT devices to close vulnerabilities

Segment networks to isolate sensitive systems and limit breach impact

Implement strict access controls based on roles and least privilege

Continuously monitor for suspicious activity with AI-enhanced cybersecurity tools

These steps are non-negotiable for maintaining system integrity and operational continuity in 2025’s smart factories.

Evolving Threats Demand Adaptive Strategies

Cyber attackers evolve rapidly, using AI themselves to identify weaknesses and mimic legitimate traffic. Staying ahead requires:

- Continuous adaptation of defense tactics

- Integrating cybersecurity directly into manufacturing workflows

- Training staff on new risks and response protocols

The era when “IT handles security” is over; it’s now a shared responsibility across manufacturing teams.

Smart factories that embrace edge computing alongside proactive cybersecurity will unlock faster operations without sacrificing safety or reliability. This balance is a cornerstone of manufacturing resilience and competitiveness in 2025.

“Edge computing slashes decision delays to milliseconds—this is where smart manufacturing meets real-time control.”

“Cybersecurity in manufacturing isn’t just IT’s job anymore; it’s the whole team’s mission.”

“Fortify your factory by segmenting networks and empowering AI-based threat detection to stay one step ahead.”

Driving Digital Transformation and Organizational Change in Manufacturing

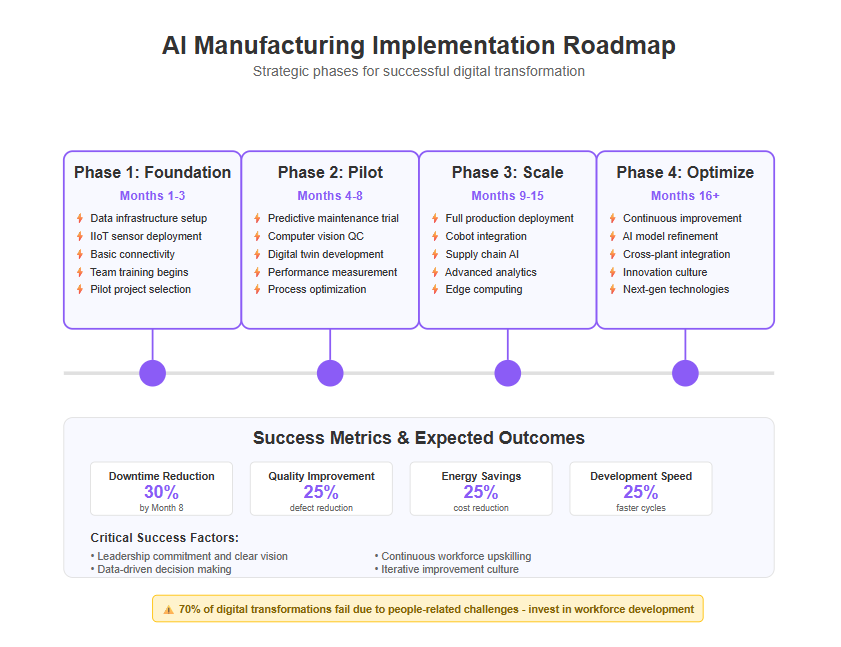

Adopting AI and smart factory tech isn’t just plug-and-play—it demands clear roadmaps that blend AI, cloud computing, and data-centric strategies into one agile plan.

With the rapid pace of technological change, manufacturing organizations must continuously adapt and learn to stay competitive.

A thoughtful digital transformation plan helps you avoid costly pitfalls and accelerates measurable gains.

Crafting Roadmaps and Balancing Upskilling

Successful transformation balances two pillars:

- Strategic tech adoption: Prioritize scalable AI tools that integrate smoothly with existing systems.

- Workforce upskilling: Train employees on new digital workflows, AI management, and data analytics.

This dual approach ensures your team evolves alongside your tech, reducing resistance and boosting adoption rates.

Statistics show that nearly 70% of digital transformations fail due to people-related challenges — so investing in your workforce is non-negotiable.

Leadership Drives Culture and Overcomes Resistance

Leaders set the tone for innovation by fostering:

- An agile, experimentation-friendly culture

- Open communication channels for feedback and problem-solving

- Accountability frameworks that own successes and failures alike

Picture a factory floor where workers feel empowered to suggest AI workflow tweaks or spot integration glitches early—that’s the culture to build.

Common obstacles include fear of job loss, unclear value propositions, and siloed teams. Overcoming these needs transparency, pilot projects, and clear communication of AI’s role as a supportive tool, not a replacement.

Practical Examples and Tips to Get Moving

- Start with small, focused AI pilots that solve real manufacturing pain points (e.g., predictive maintenance or quality control).

- Use data dashboards to track key performance indicators (KPIs) and visibly celebrate wins.

- Regularly gather front-line worker input to continuously refine technologies and processes.

Remember: digital transformation is a marathon, not a sprint. Consistent iteration and leadership buy-in are your secret weapons.

Driving digital change is about more than just technology—it’s about weaving AI and cloud-powered tools into your company’s fabric while empowering your people. When done right, you accelerate innovation, boost resilience, and create a future-ready manufacturing culture that thrives beyond 2025.

Spotlight on Breakthrough AI Technologies Revolutionizing Manufacturing in 2025

In 2025, manufacturing’s smartest breakthroughs hinge on seven AI technologies that boost productivity, cut costs, and make factories truly intelligent. Emerging technology and rapid AI adoption are driving the next wave of manufacturing innovation, transforming how factories operate and compete.

From advanced robotics doing complex assembly to computer vision inspecting every product at lightning speed, these innovations redefine what’s possible on the production line.

AI Innovations Driving Smarter Manufacturing

Here are the top AI techs shaping this revolution:

- Advanced Robotics & Cobots: Robots working side-by-side with humans, enabling safer, flexible workflows

- Computer Vision: Real-time defect detection that slashes scrap rates and speeds up quality control

- Natural Language Processing (NLP): AI analyzing unstructured data like maintenance logs, boosting predictive accuracy

- Reinforcement Learning: Self-optimizing systems learning the best production parameters without human intervention

- Digital Twins: Virtual replicas offering continuous simulation and foresight for decision-making

- Edge AI Processing: Instant data crunching at the machine, ensuring ultra-low latency responses

- AI-Powered Analytics: Deep insights across supply chains and operations driving agility and cost savings

- AI Agents: Autonomous systems embedded in platforms like Salesforce that automate decision-making, improve communication, and streamline manufacturing workflows

Together, these technologies transform factories into dynamic, responsive environments where every component—from robot arms to supply chains—learns and adapts.

Emerging Trends & Future Breakthroughs to Watch

Expect to see rapid growth in AI systems that:

- Fuse reinforcement learning with robotics, enabling autonomous process improvements

- Integrate NLP with real-time analytics, turning voice commands and text notes into action triggers

- Expand edge AI’s role in critical safety and quality decisions, cutting response times to milliseconds

AI integration is enabling seamless collaboration between different AI systems and manufacturing processes, connecting autonomous systems to business operations for enhanced efficiency and digital transformation.

Imagine a robot that not only assembles parts but also talks with operators, learns from environment changes, and instantly flags potential defects before they happen.

Why You Should Experiment Now

Early adopters who pilot these AI tools see measurable results: 30% reductions in downtime, 25% faster production cycles, and up to 40% cost savings on quality control. Early experimentation with AI tools also provides a competitive edge in the manufacturing industry, helping companies stay ahead of evolving trends and outperform competitors.

If you’re a startup or SMB aiming to scale, now’s the time to test and integrate these innovations before they become industry standards.

- Start with small-scale cobot deployments or AI-driven inspection systems

- Leverage edge computing to accelerate local decisions without latency

- Use NLP analytics to unlock hidden insights from your operational data

Exploring these tools actively prepares your operation for smarter, faster manufacturing—and positions you to ride the AI wave confidently.

“Manufacturing in 2025 isn’t just automated. It’s intelligent, collaborative, and adaptive.”

“Think of AI breakthroughs like adding a sixth sense to your factory—seeing defects before they occur and learning on the fly.”

Embracing these technologies isn’t a luxury; it’s a survival strategy in today’s competitive markets.

Mastering the right mix of AI-powered tools is your shortcut to flexible, efficient production that scales as your business grows.

Mastering Quality Control Through AI: Smarter Inspection for Reliable Products

Quality control is evolving fast, powered by AI-driven computer vision and data analytics that catch defects humans often miss.

AI-driven quality control is transforming both production processes and manufacturing processes, delivering greater reliability and consistency across the board.

Real-time AI inspection systems analyze every product on the line, instantly detecting and classifying defects with unmatched speed and precision.

Why AI Quality Control Matters Now

Traditional inspection methods can let flaws slip through or slow down production. AI can:

- Reduce scrap and rework by catching issues early

- Cut warranty costs linked to faulty products

- Boost throughput without sacrificing accuracy

- Improve production efficiency by reducing rework and speeding up inspections

Statistics show manufacturers integrating AI inspection reduce defect rates by up to 40%, saving millions annually on operational inefficiencies and customer claims.

How AI Inspection Systems Work

These systems combine cameras, sensors, and machine learning models trained on thousands of examples. The workflow typically follows:

Continuous image capture along production lines

AI analyzes patterns to spot irregularities like cracks, misalignments, or color variations

Real-time monitoring enables instant defect detection and correction, with instant alerts or automatic line adjustments preventing defective products from advancing

For instance, electronics manufacturers use AI to detect soldering faults invisible to the naked eye, while automotive factories identify paint imperfections in seconds rather than hours.

Making AI Work for Your Quality Goals

Adopting AI QC means integrating these inspection tools with existing production and data systems for seamless operations. Integrating AI inspection tools helps enhance efficiency across quality control operations. Key benefits include:

- Real-time feedback loops to quickly optimize production parameters

- Data-driven insights enabling predictive quality improvements

- Scalability across varied product lines and complexity levels

Visualize a smart line where each unit is scanned and analyzed like a hawk-eyed inspector catching every flaw without slowing down the pace. Performance and reliability both shoot up.

Smarter, AI-powered quality control lets manufacturers cut costs, speed up production, and deliver consistently reliable products. This isn’t just a tech upgrade—it’s a game plan for winning customer trust and operational excellence in 2025 and beyond.

“AI inspection today isn’t about replacing human judgment—it’s about turbocharging it for flawless results.”

“Real-time defect classification is the difference between reactive fixes and proactive perfection.”

“Imagine cutting your scrap rate almost in half while speeding up QA cycles—AI makes that possible.”

Conclusion

AI is transforming manufacturing from a rigid, manual system into a smart, agile powerhouse—helping you boost efficiency, cut costs, and stay competitive in 2025 and beyond. Across the manufacturing sector, AI is driving industrial transformation by reshaping the manufacturing landscape with advanced automation, predictive analytics, and intelligent tools that enable innovation and resilience. By harnessing AI-driven automation, real-time data insights, and human-machine collaboration, your factory floor can become a dynamic environment where innovation thrives and downtime shrinks.

Here’s how you can take charge of this shift today:

- Implement AI-powered predictive maintenance to catch equipment issues before they disrupt your workflow.

- Use computer vision for real-time quality control that slashes defects and waste.

- Start building an IIoT-connected ecosystem that links machines, sensors, and people for seamless communication.

- Invest in upskilling your workforce to collaborate effectively with AI and cobots.

- Explore digital twins and edge computing to simulate decisions and accelerate response times.

Don’t wait for AI to be “just another tool.” Make it the backbone of your manufacturing strategy—the difference between reacting to problems and anticipating them.

Take one practical step today: whether it’s piloting an AI inspection system, launching a small predictive maintenance project, or mapping out your digital transformation roadmap. Momentum builds fast when you act.

Remember: smart manufacturing isn’t about replacing people, it’s about empowering them with AI-powered tools to build stronger, faster, and greener operations.

Your factory’s future is already here—ready to think faster, adapt instantly, and outpace the competition. What will you build with it?